Controlling the log turner

This product can be used to correct turning errors or continuously measure log rotation

About

Software for rotation control

Taigatech's algorithm is designed for maximum precision, robustness and simplicity. Log rotation can be measured in the toughest conditions, completely independent of transducer, laser or measuring frames.

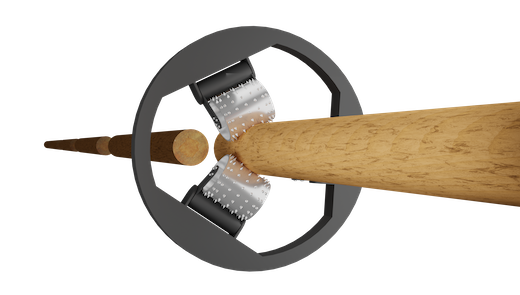

Small housing

The camera housing is constructed of durable aluminum and built to take up minimal space. The placement is flexible and can be adjusted according to space.

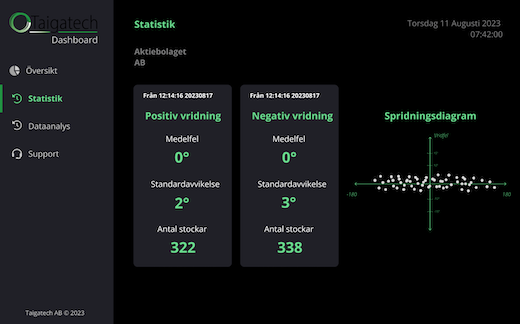

User friendly interface

With a stylish user interface, it is easy to track the log turner's performance and statistics over time. Choose between measuring or correcting the errors, follow trends, identify systematic errors and start working with preventive maintenance.

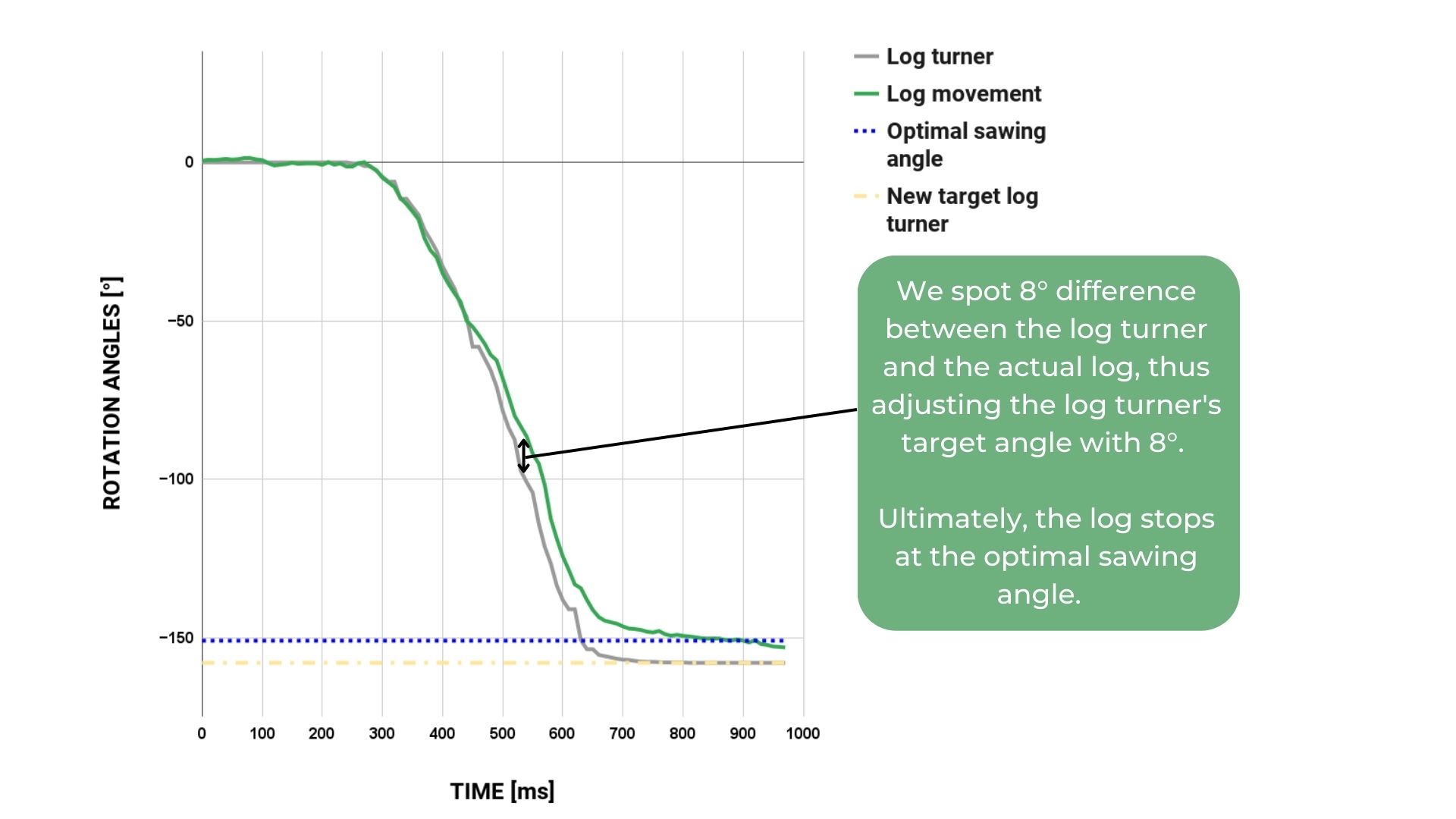

How it works Log turning control is a simple upgrade that realizes the full potential of existing production. The system measures the rotation of the log in front of the saw and can be integrated into the control system regardless of the supplier of the measuring frame and saw line. By feeding back to the control system in real time, it controls the rotary encoder to counteract the measured deviation.

Control the log turning

The position of the log is calculated in real time. The current angle is compared with the servo’s position. This happens very quickly, which enables the system to give the rotary servo new instructions during the turning process itself to optimize the rotation of the log to an optimized sawing angle. The graph on the right shows how Taigatech's system corrects a log’s angle.

Seamless integration

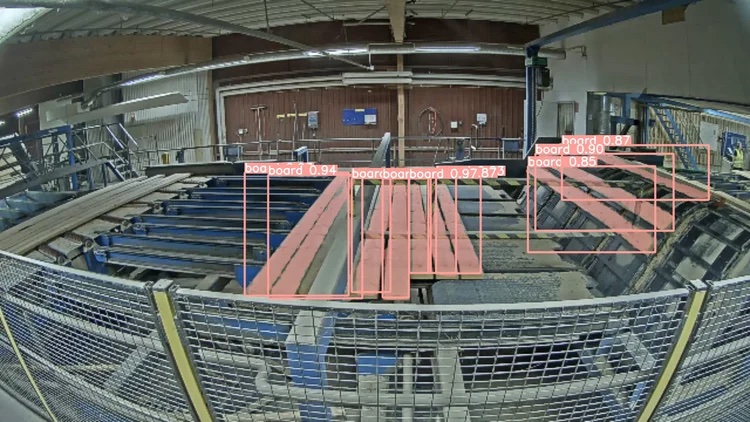

Taigatech develops a construction concept that requires minimal space. The cameras are placed next to the saw. We re-optimize calculations according to your specific conditions. The program is built to seamlessly interact with production for start and stop. The operator can easily choose between either continuously measuring or correcting the measured deviations.

Great savings

Turning errors have a great impact on saw and value exchange, as well as production stoppages. Having a well-functioning round turning helps to increase profit and reduce raw material costs.

Other productsSolutions for saw mills

Fingerprinting

Digitizes production and enables a more flexible machine park by sharing data with fingerprinting technology.

Process surveillance

Increase productivity and avoid down-time by automated process surveillance utilizing your existing hardware.