Correct deviations or continuously monitor for unparalleled precision and efficiency

The log turning system to maximize the potential of your production

Real-time monitoring and precise control of the log

Unlock peak performance from existing machinery

Highly precise measurements

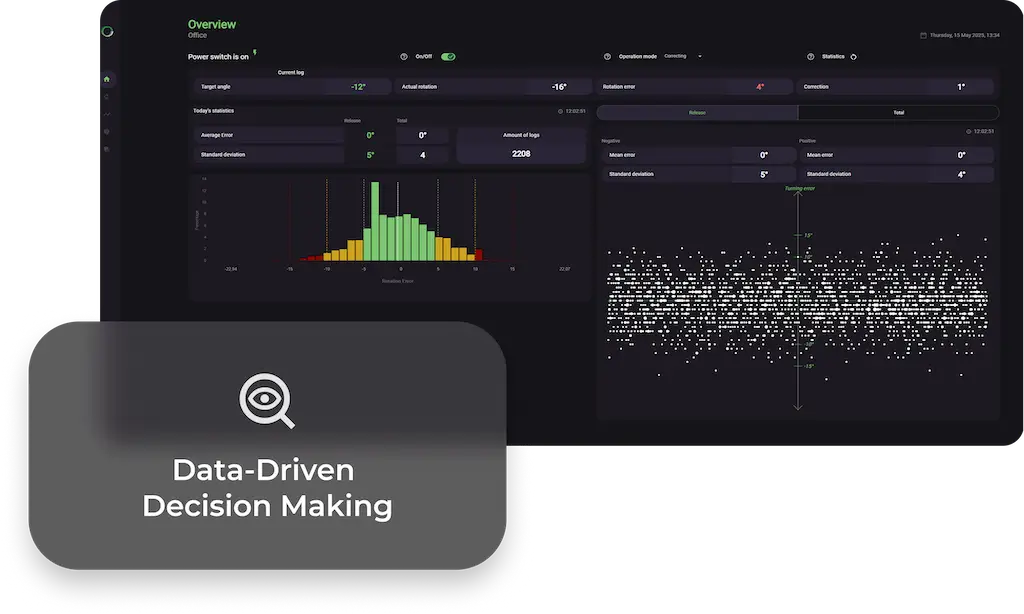

Highly precise measurements Data-driven optimisation

Data-driven optimisationWhy choose us

We are your partner for yield increase

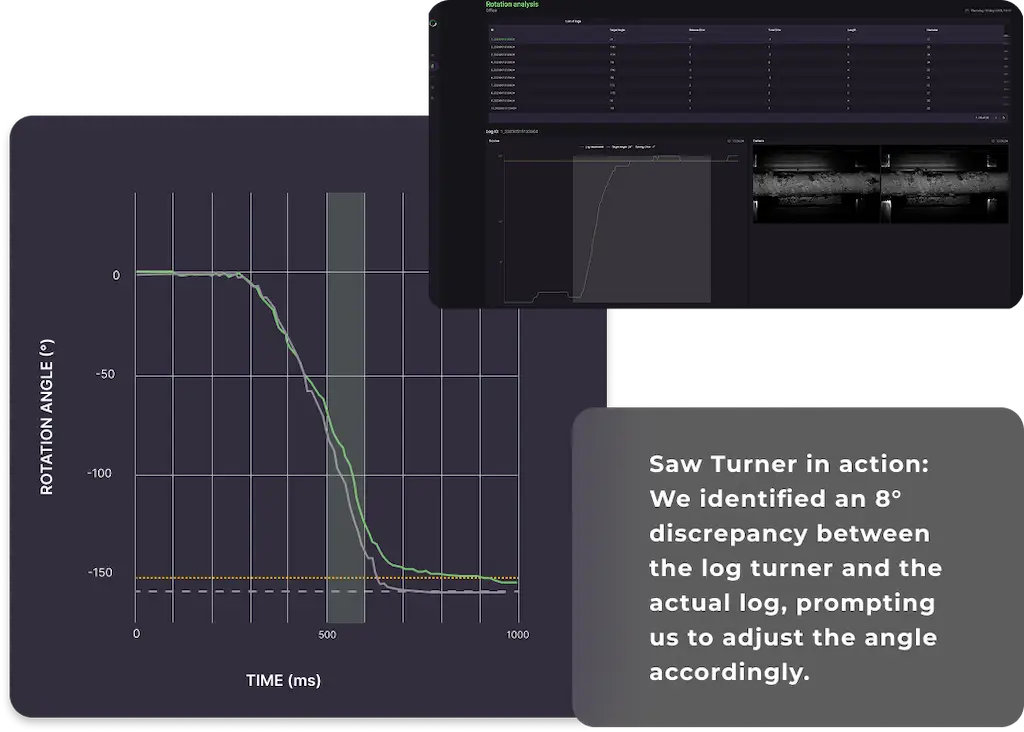

Software for precise rotation control

Taigatech's algorithm is designed for maximum precision, robustness and simplicity. Log rotation can be measured in the toughest conditions, completely independent of transducer, laser or measuring frames

Compact camera housing

The camera housing is constructed of durable aluminium and built to take up minimal space. The placement is flexible and can be adjusted according to space.

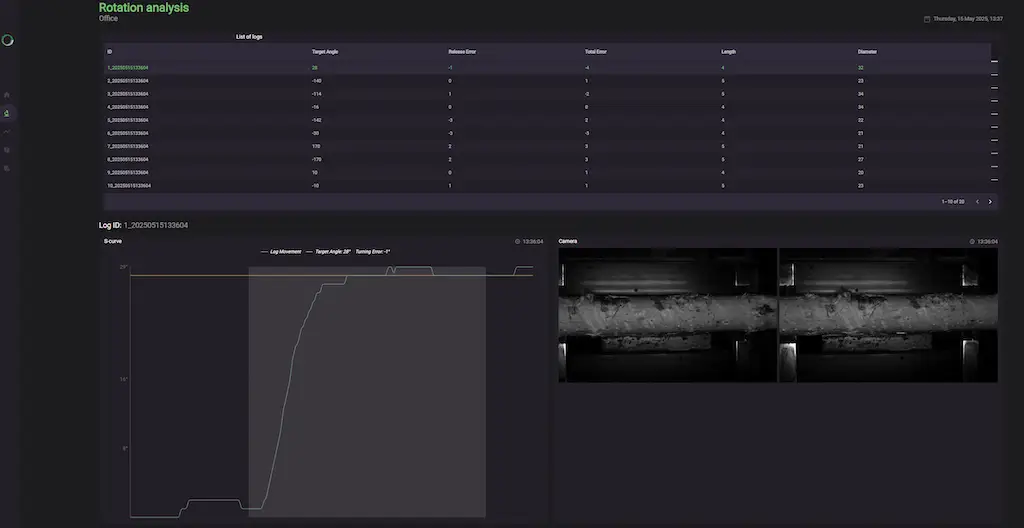

User friendly interface

The accessible user interface allows you to effortlessly monitor the log turner's performance and statistics over time. You have the option to either measure or correct errors, giving you complete control over your operations.

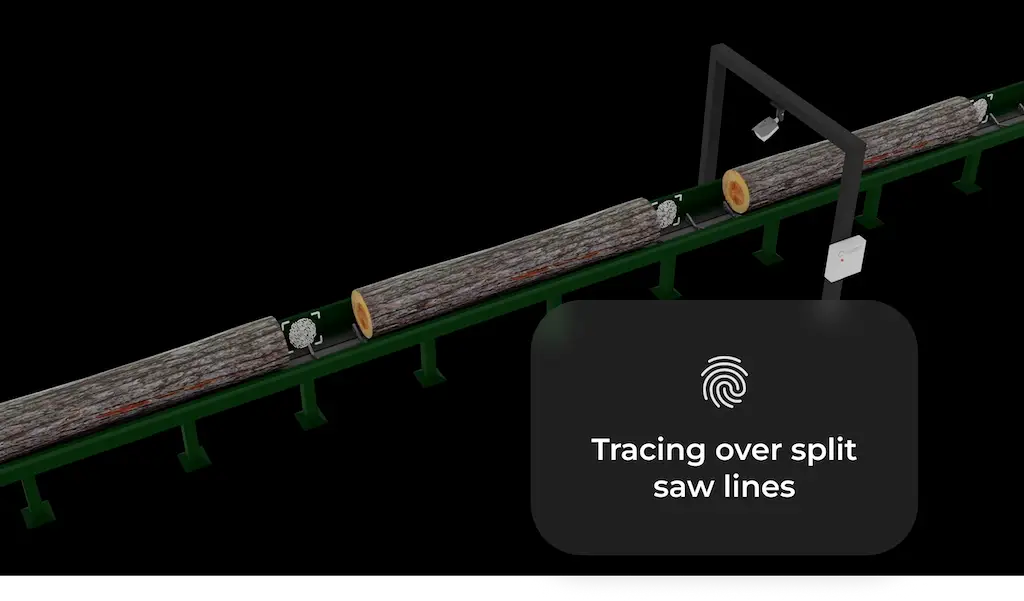

How it works

A simple upgrade to unlock maximum performance

1. Real-Time Log Tracking: The system constantly and instantly determines the exact position of the log as it's being turned.

2. Instant Angle Comparison: It then immediately compares this log angle with the servo's position.

3. Dynamic Servo Adjustment: Rapid comparisons enable the system to send new commands to the servo mid-turn, dynamically fine-tuning rotation for the perfect sawing angle.

4. Visualizing Precision: Finally, through our user interface, you can observe firsthand how Talgatech's system actively corrects any deviations in the log turning

make great savings

Turning errors have a great impact on saw and value yield, as well as production stoppages. Having a well-functioning turning system increase profit by improving raw material usage.

Advance analytics

Follow the daily performance of the log turning, historical data and make your own analysis against log properties. Identify systematic errors and start working with preventive maintenance.

Traceability and quality control

Taigatech uses AI and computer vision to create a unique ID for each log based on its uniqueness, enabling full traceability through sawmills. This system collects valuable log data, and verifies log turning.