Our solutions contribute to a sustainable forest industry

With our innovative solutions, we help saw mills increase productivity, availability and saw yield. With cutting edge expertise in computer vision, together with innovative engineering, we create tomorrow’s solutions for a sustainable forest industry.

Explore our productsProducts for saw millsOur solutions

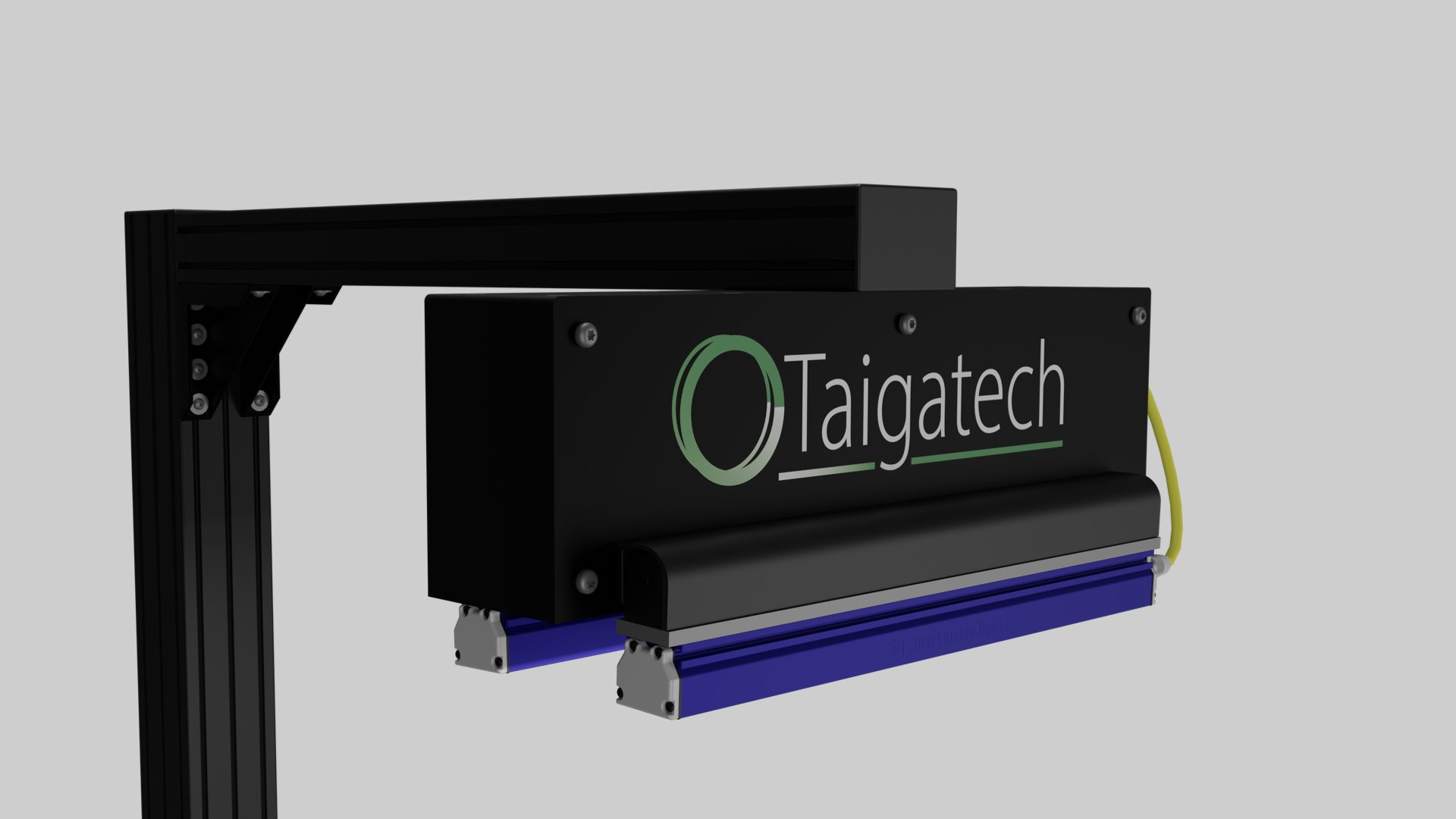

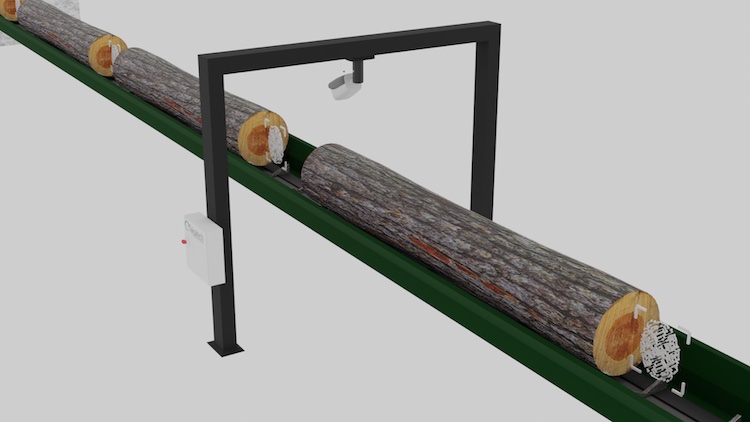

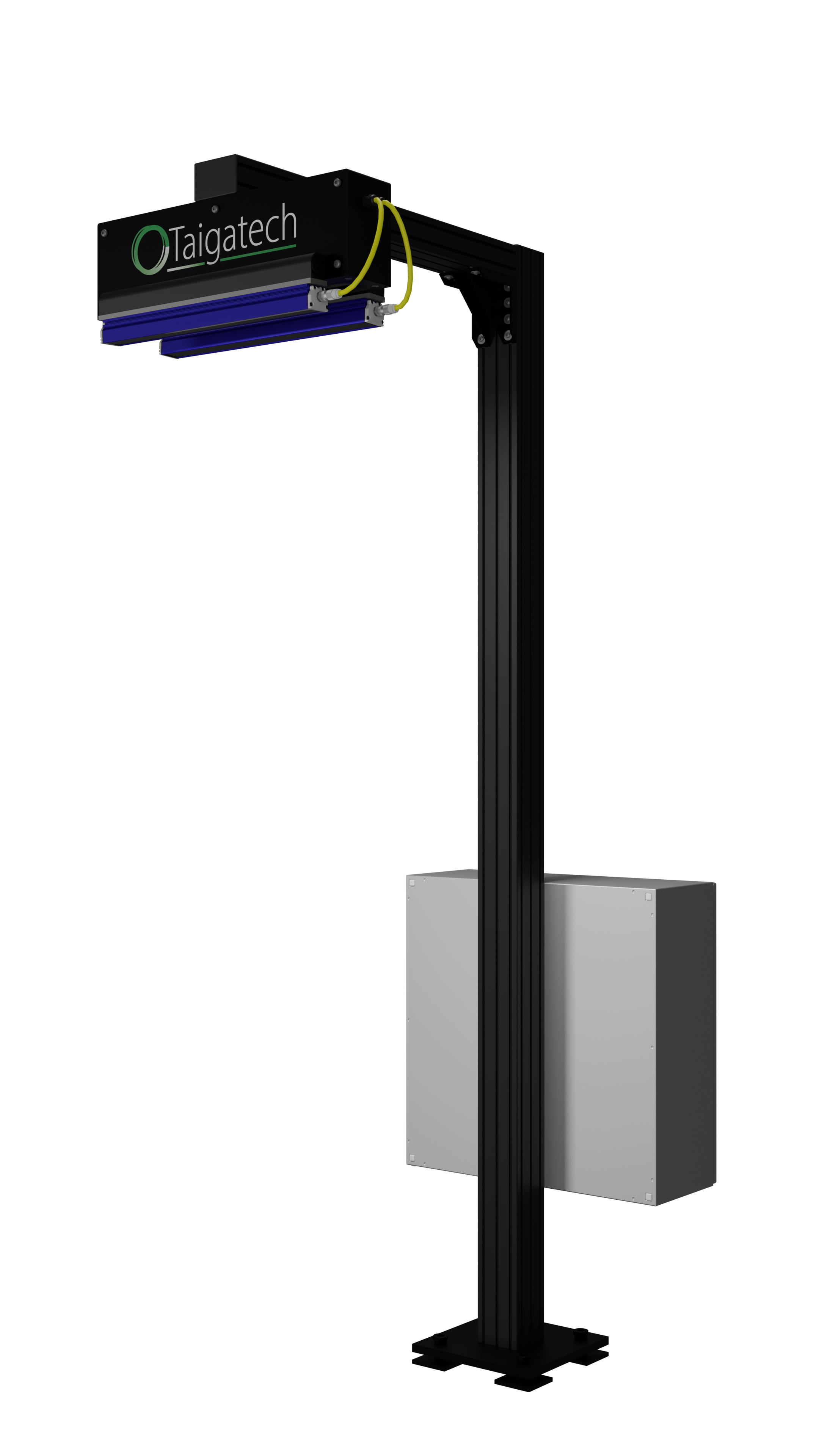

Measures the log movement and controls the log turner to improve your saw yield

Our camera vision system tracks the trajectory and rotation of the log before the first saw group. We detect any deviation and control the machine to correct the rotation during the process. As a result, deviations are avoided and the saw yield is greatly improved.

Monitoring process flows of logs and boards to maintain production capacity

Optimize your processes with advanced AI. We teach our programs to analyze the image streams from existing cameras to detect production errors and correct them. The solution increases both production capacity and prevents machine problems.

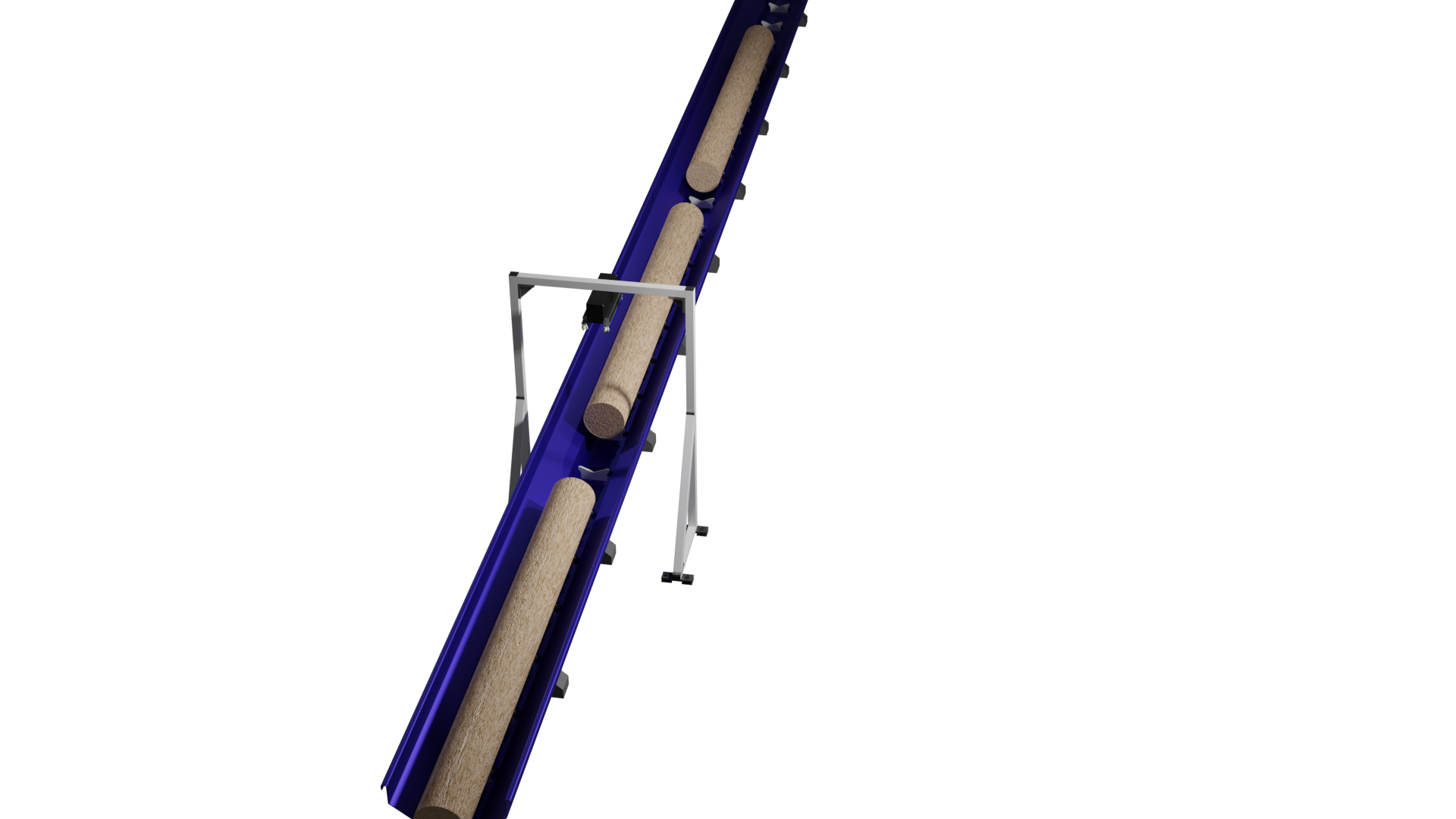

Digitizing production with a unique fingerprint to identify and index every log

The solution when you can’t fit a log scanner into the saw house. We use cameras to track and recognize a log through an image of the end surface. It provides the opportunity to digitize production and move measurement data along the saw lines, or to do the log scanning in a different location than in front of the saw.

Camera-based systems

We specialize in interpreting images and creating innovative solutions for smart production. This includes recognizing logs among thousands of others, accurately calculating movements and rotations, as well as quickly giving feedback through intelligent algorithms.

Modularity

We are happy to tailor our solution to your needs. Our technology is modular and increases the potential of your existing production. Our products have been integrated in several sawmills with different setups and conditions.

Fast & flexible

We ensure a quick and safe installation. Our goal is always to minimize redesign of existing production and plan the installations to avoid production stoppages.

Better results with AI from Taigatech

Increased efficiency

Get more from your machine park. Today, many processes are analyzed manually or not at all, which creates big questions about how downtime is to be reduced or why yield is lost. Several of our innovative solutions contribute to increased profitability by creating new functions on existing machines.

Insights

Use Taigatech's products to analyze the current situation with high precision.

Data analysis

We understand and interpret situations, identify patterns and build robust solutions based on your needs.

Control systems and automation

We integrate our solutions into your control through communication to PLC:s