Based on Computer Vision

Through the latest research in computer vision, we can apply sophisticated solutions and algorithms to previously unsolved problems

About fingerprinting

Innovative AI-software

The software used to perform the image matching is based on world-leading AI-technology thanks to Taigatech's excellence in image analysis and computer vision.

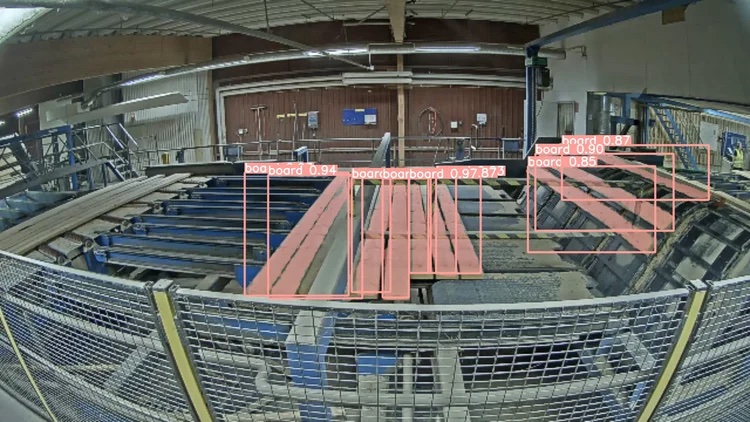

Tracing over split saw lines

We identify the log in order to maintain a correct queue system across saw lines where the logs are at risk of changing order, for example log tables and ladder feeders.

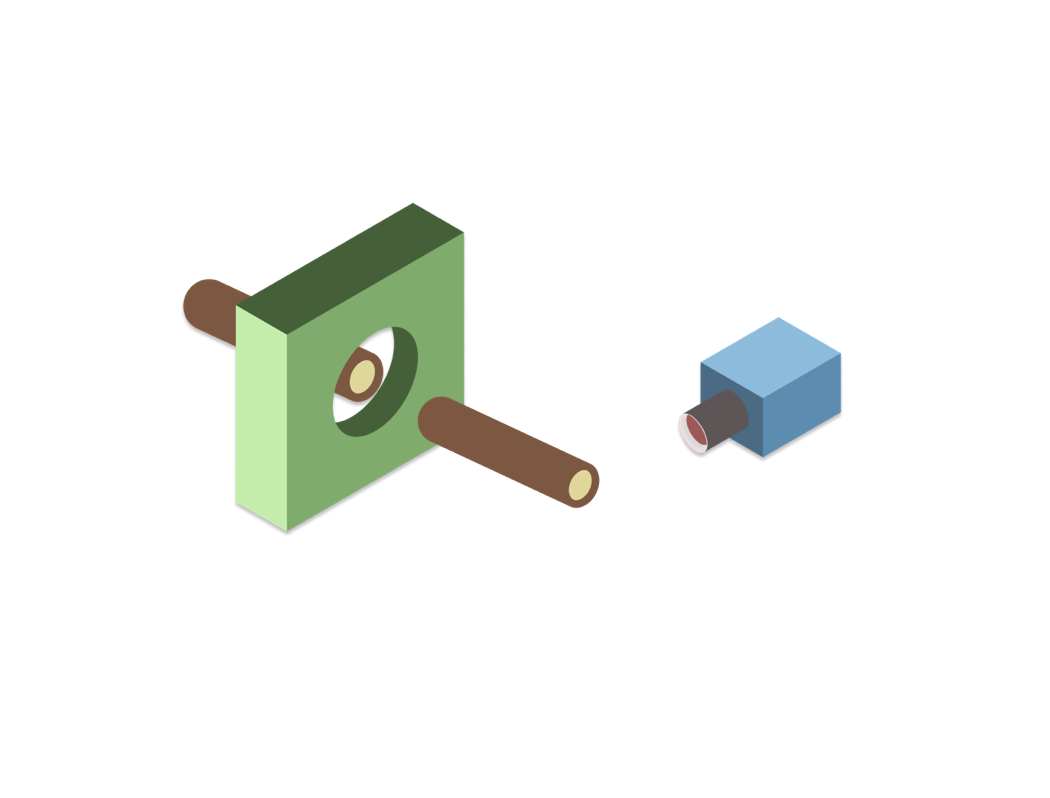

Move scanner data

If there is no space for a log scanner or saw optimization in the saw house, we can photograph the end surface in connection with the saw optimization and recognize the log's position before insertion. This means that you can do optimization in another place and move the measurement data to the saw.

About traceabilityTwo cameras are easily mounted according to the customer needs. Traceability on an individual level is then created for each log between these two points. By simply photographing the end surface of the log, the user can follow each log through the entire sawmill.

Pricing and measurement

During the measurement, valuable information about the log is collected such as length, thickness, location of twigs and internal structure. This information is important for sorting the log into the correct timber class during timber sorting. The same information can then also be used at the time of sawing.

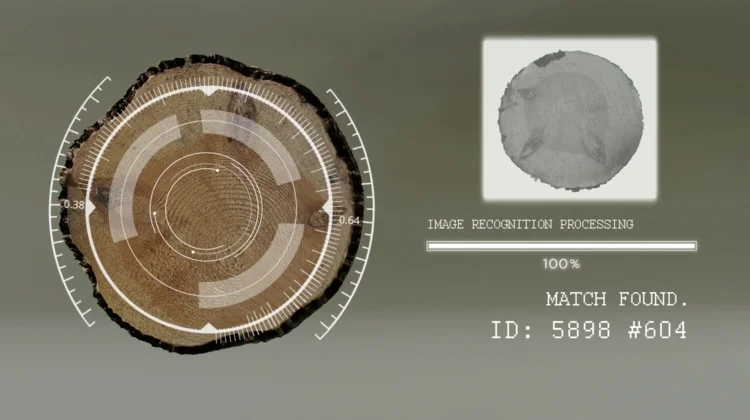

Unique ID

In connection with retrieving valuable information about the log, a photo is taken on the end surface of the log. The end surface is as unique as a fingerprint. Therefore a unique ID can be created based on the end surface. The log then becomes its own information carrier. The unique ID is saved in a database and can be matched at any time by simply taking a new photo of the end surface of the log in production.

Log sorting

Because the log is its own information carrier, all valuable information about the log follows through the entire production chain. It is therefore possible to identify each individual log when sorting timber and get a better overview of all logs in each timber class. This system creates opportunities to ultimately reduce inventory costs by gaining better control of the log inventory.

Saw intake

During the production flow, the end surface of each individual log is matched against the unique IDs found in the database and the valuable information available about each log can then be used. By make full use of the information associated with each log, the sawmills can, for example, optimize log twisting or verify that the log is turned in optimally.